Leading gaming

equipment

FINISHED PROJECTS

Sold to countries

satisfied clients

Technology Patent

4260+

Projects Completed+86 -18651836917

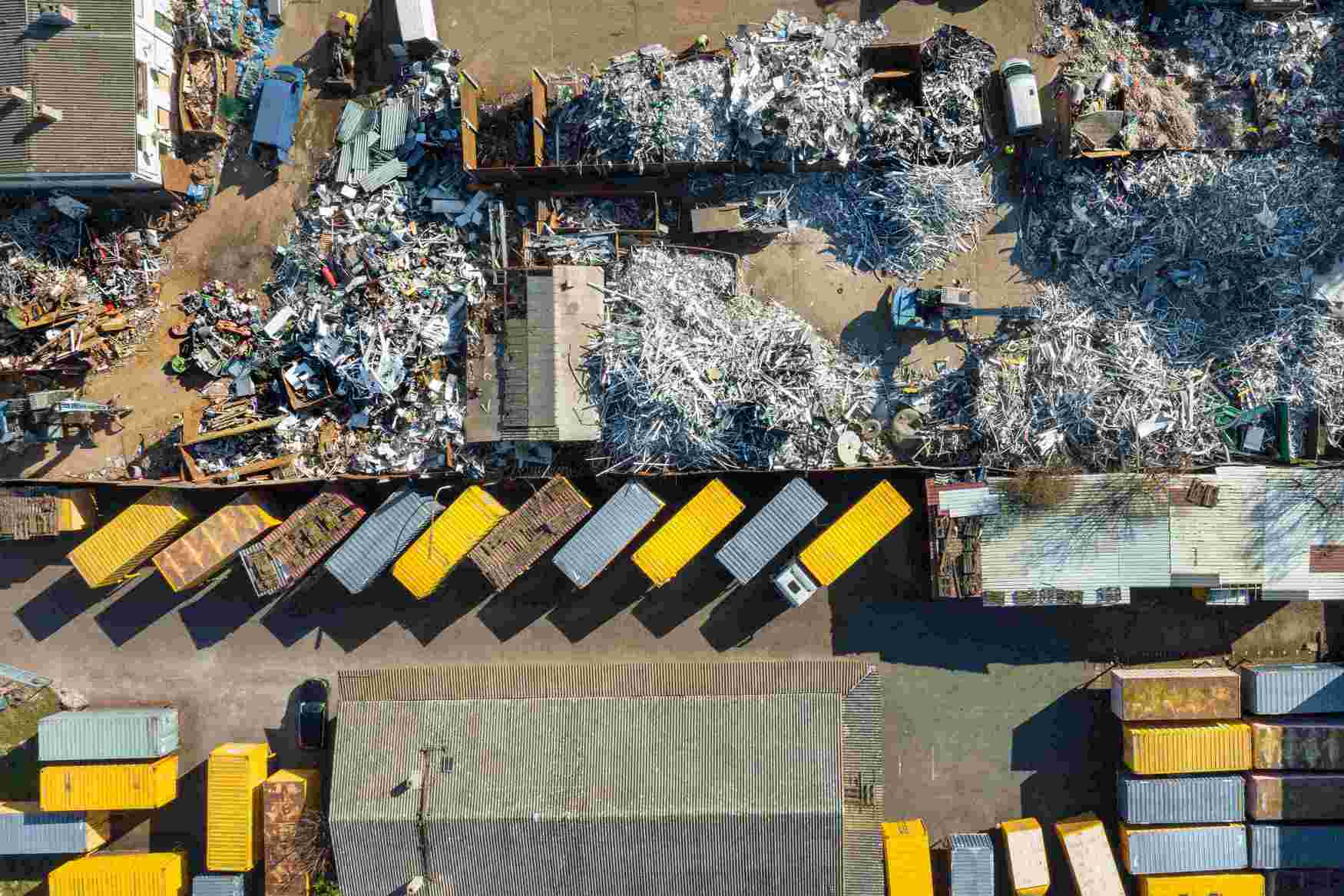

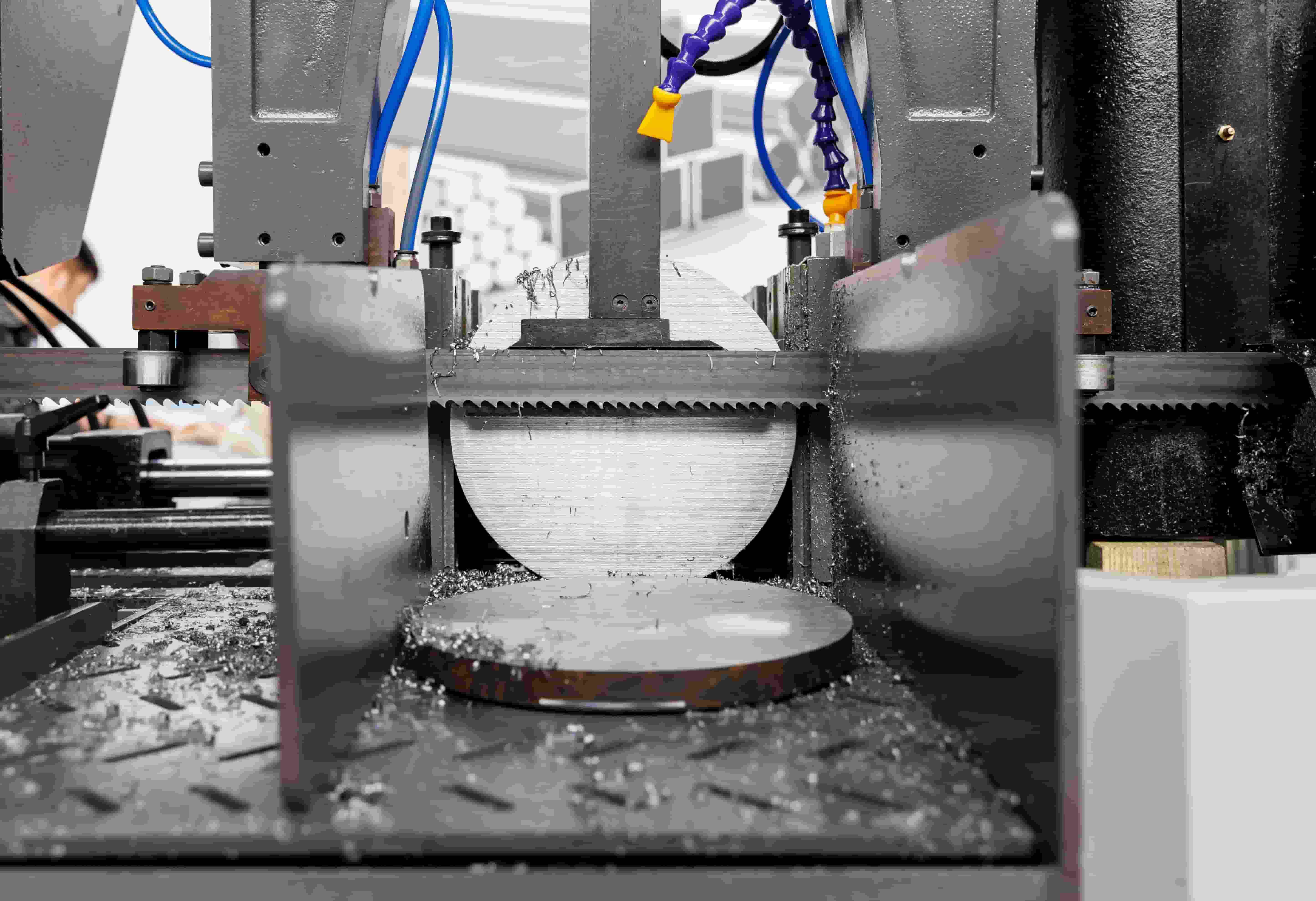

1000T Scrap Cutting Machine Multi Blade Gantry is an efficient and precise metal shearing equipment, widely used in scrap metal recycling, steel structure processing, automobile dismantling and other industries. It adopts a gantry structure design, equipped with multiple shear blades, and can achieve rapid cutting of high-strength metal materials through hydraulic or mechanical drive. It has the characteristics of strong stability, large shearing force and high working efficiency.

Read More

500T Heavy-Duty Scrap Shear – Multi-Blade Gantryis an efficient and precise metal shearing equipment, widely used in scrap metal recycling, steel structure processing, automobile dismantling and other industries. It adopts a gantry structure design, equipped with multiple shear blades, and can achieve rapid cutting of high-strength metal materials through hydraulic or mechanical drive. It has the characteristics of strong stability, large shearing force and high working efficiency.

Read More

Scrap briquetting machine is a kind of equipment used to compress various metal or non-metal waste into high-density blocks. It is widely used in the recycling industry, which can effectively reduce the volume of waste, facilitate transportation and storage, and improve the recycling rate of waste.

Read More

Scrap briquetting machine is a kind of equipment used to compress various metal or non-metal waste into high-density blocks. It is widely used in the recycling industry, which can effectively reduce the volume of waste, facilitate transportation and storage, and improve the recycling rate of waste.

Read More

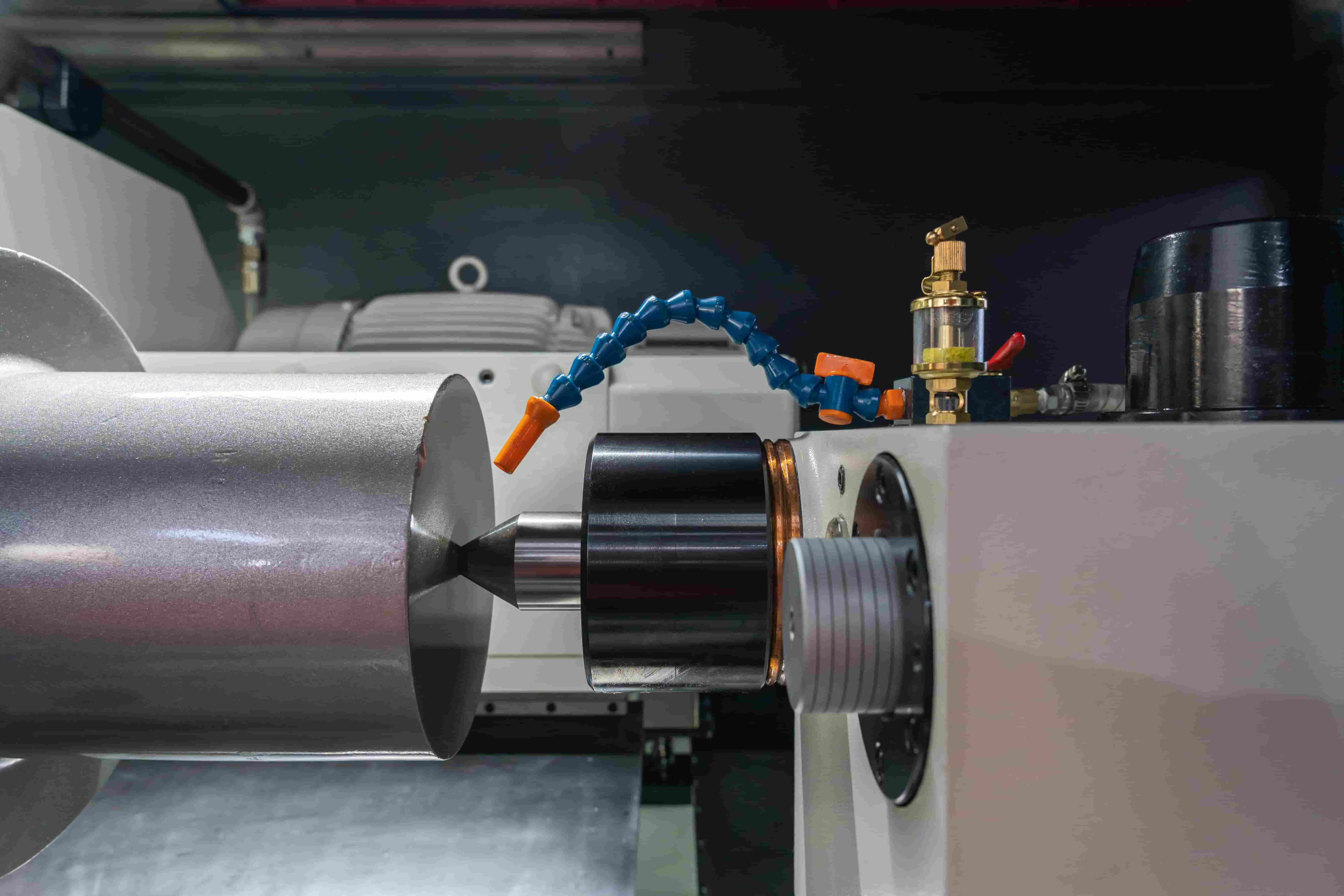

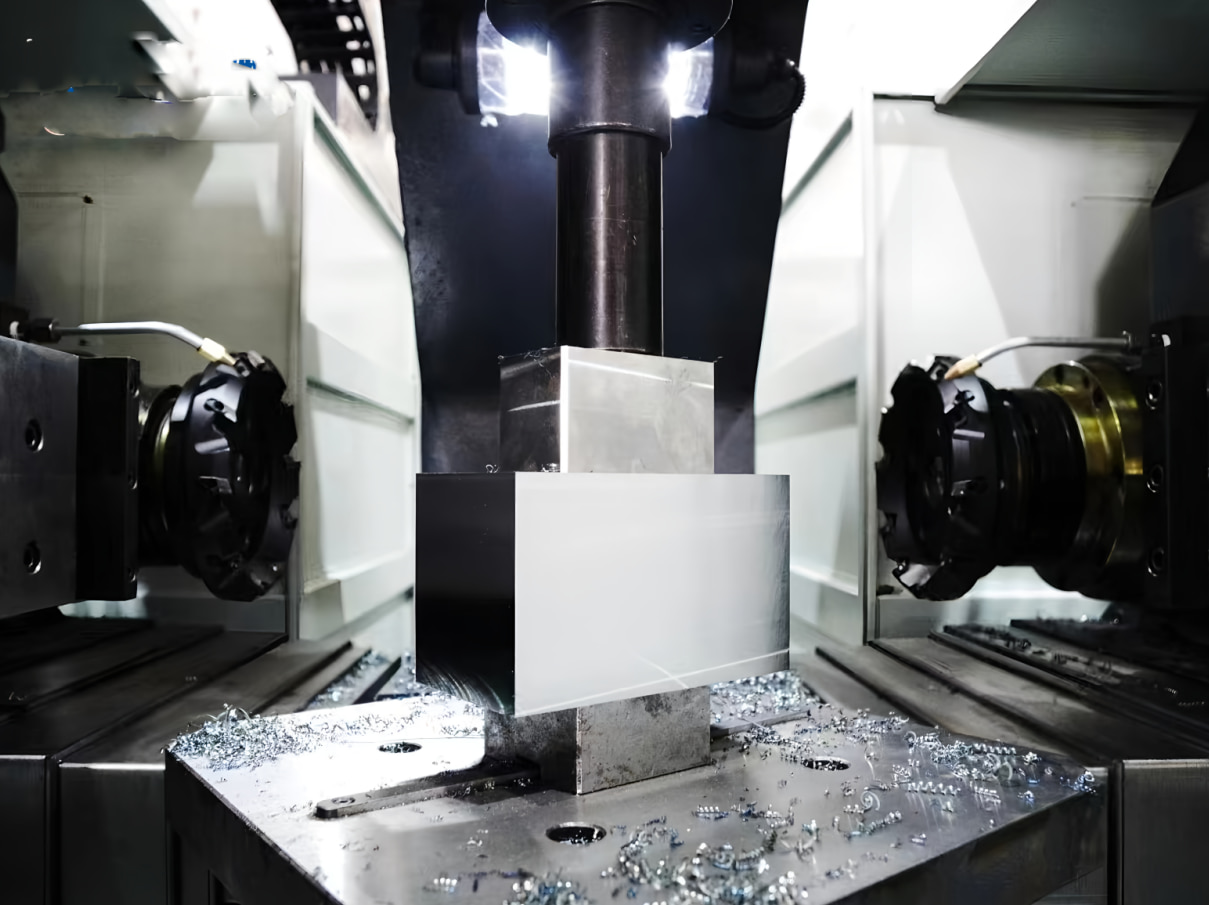

Made of high-quality alloy tool steel or high-speed steel, it has undergone special heat treatment process and has extremely high hardness and wear resistance. Mainly used for straight-line cutting of scrap steel S7 steel is an impact-resistant tool steel, which is characterized by good hardenability, high strength and tempering stability, and good comprehensive performance. Due to its high toughness and medium-temperature oxidation resistance, it is suitable for manufacturing tools and dies working under high temperatures and high impact loads, and is also suitable for manufacturing hammer forging dies.

Read More

Cr12MoV steel has become the mainstream choice for precision cold working molds due to its high wear resistance, moderate toughness and excellent dimensional stability. It is especially suitable for scenarios with strict requirements on edge retention and mold life. Made of high-quality alloy tool steel or high-speed steel, it has undergone special heat treatment process and has extremely high hardness and wear resistance. Mainly used for straight-line cutting of scrap steel

Read More

G55SiMoV is a high-carbon high-alloy bearing steel. This steel has a reasonable silicon (Si), molybdenum (Mo), and vanadium (V) alloying design. While ensuring high hardness and wear resistance, it also improves the material's fatigue resistance and high temperature stability. Made of high-quality alloy tool steel or high-speed steel, it has undergone special heat treatment process and has extremely high hardness and wear resistance. Mainly used for straight-line cutting of scrap steel

Read More

Made of high-quality alloy tool steel or high-speed steel, it has undergone special heat treatment process and has extremely high hardness and wear resistance. Mainly used for straight-line cutting of scrap steel S7 steel is an impact-resistant tool steel, which is characterized by good hardenability, high strength and tempering stability, and good comprehensive performance. Due to its high toughness and medium-temperature oxidation resistance, it is suitable for manufacturing tools and dies working under high temperatures and high impact loads, and is also suitable for manufacturing hammer forging dies.

Read More

Material Sourcing as project requirement.

Strict Quality Control

Good Communication and Fast Feedback

48 hours fast delivery

26

February12

January28

December19

December15

December

Building C 2015, Xingzhuang Science and Technology Industrial Park, No. 288 Qinhuai Avenue, Yongyang Street, Lishui District, Nanjing City, Jiangsu Province

IPv6 network supported

IPv6 network supported