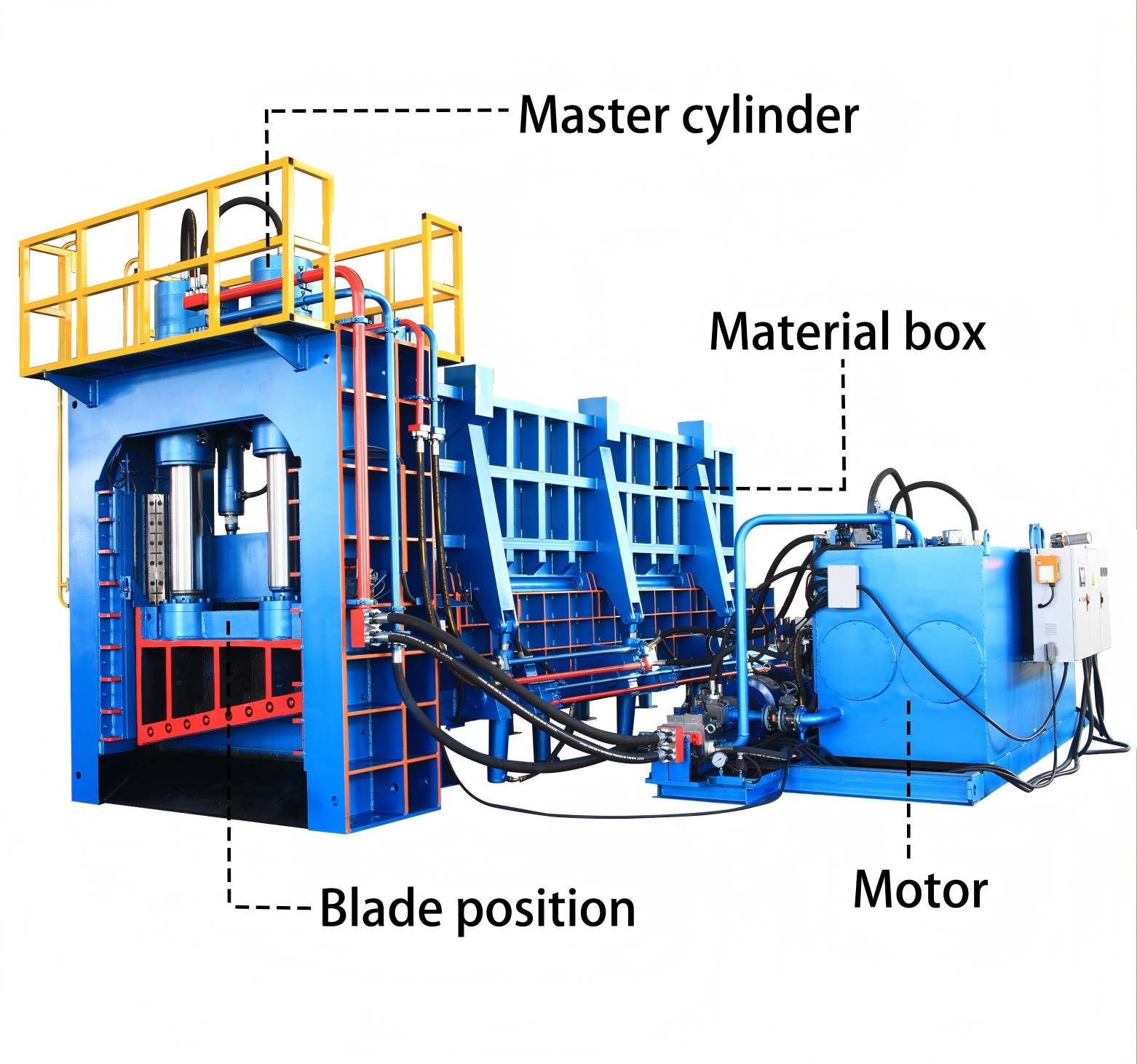

Our 500T Heavy Hydraulic Gantry Shearing Machine is designed for large-scale metal recycling operations. This robust machine provides powerful shearing force for processing heavy and oversized scrap metal, including steel plates, beams, pipes, and structural components. It ensures precise cutting, high productivity, and low maintenance, making it the ideal choice for scrap yards, steel mills, and metal processing plants.

Customized :

YESApplication :

SCRAP RECYCLINGOrder(MOQ) :

1 SetLead Time :

30 DAYSShipping Port :

SHANGHAIProduct Origin :

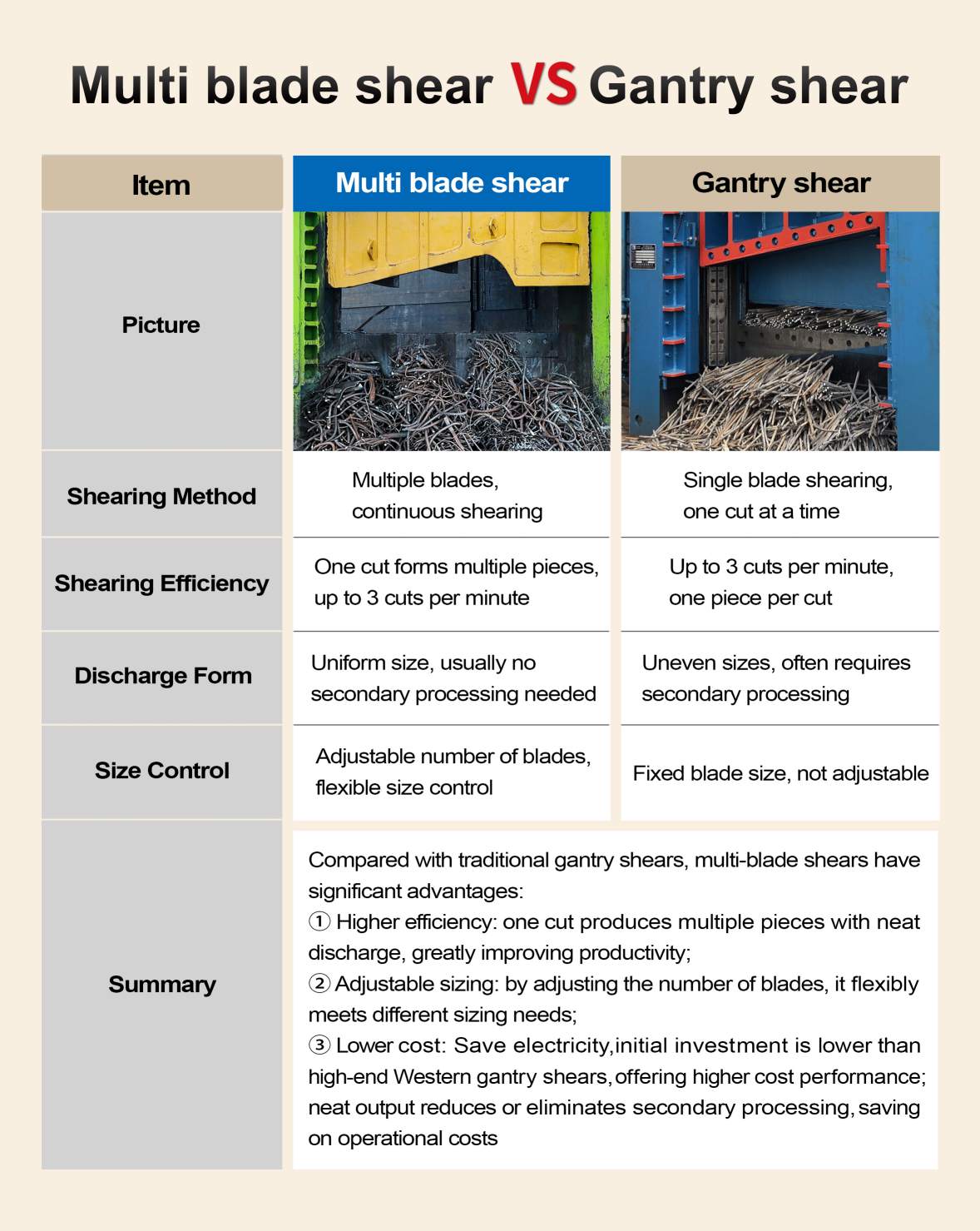

CHINAScrap Multi Blade Gantry Shear

Features

Precision Under Pressure

Heavy Hydraulic Gantry Shearing Machine — Powerful, efficient solution for cutting heavy scrap metal in industrial recycling.

High Shearing Capacity: Suitable for cutting heavy and bulky scrap materials with ease.

Durable Structure: Built with high-strength steel frame and wear-resistant blades for long service life.

Efficient Hydraulic System: Delivers stable performance and powerful shearing force.

Easy Operation & Maintenance: User-friendly control system and minimal maintenance requirements.

Customizable Specifications: Various models and cutting forces available to meet different processing needs.

Choose us for an efficient, durable, and worry-free cutting experience!

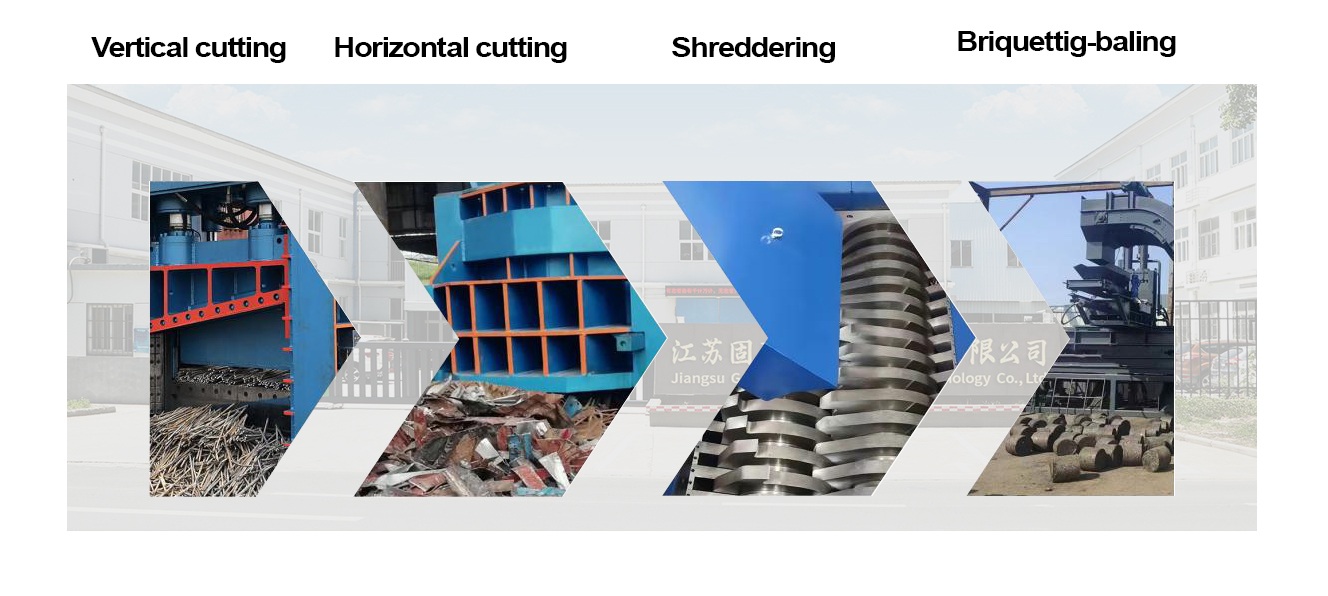

Scrap steel processing method

Parameter

| 400 | 500 | 630 | 800 | 1000 | 1250 | 1600 | 2000 |

| 55kw | 90kw | 75*2kw | 90*2kw | 90*3kw | 90*4kw | 90*5kw | 90*6kw |

| 1400mm | 1600mm | 1800mm | 2000mm | 2500/2100mm | 2500/2100mm | 2500mm | 2500mm |

| 6000×1300×500 | 6000×1500×700 | 8000×1700×1200 | 8000×1900×1200 | 8000×2000×1200 | 8000×2400×1200 | 8000×2400×1200 | 8000×2400×1200 |

Details

Application Areas

Video Showcase

FAQ

1. What materials can the multi-blade gantry shear cut?

It is mainly used to cut metal materials such as steel plates, steel bars, scrap steel, etc., and is suitable for processing medium and thick plates.

2. What are the advantages of multi-blade and single-blade shears?

It is more efficient, can cut multiple sections of materials at the same time, adapt to different shapes and thicknesses, and has a longer tool life.

3. How to maintain the equipment?

Regularly lubricate, check blade wear, keep hydraulic oil clean, and avoid equipment jams.

4. How is the shearing accuracy?

The error is small (about ±1mm), PLC controls adjustable length and angle, and the shearing is stable.

5. What parameters should be considered when buying equipment?

Mainly look at shearing force (tonnage), blade length, control system (manual or automatic) and safety functions.