Bearing steel has extremely high requirements for production technology and is a mold steel with high strength and high precision.

Customized :

YESApplication :

SCRAP RECYCLINGOrder(MOQ) :

1 TONLead Time :

30 DAYSShipping Port :

SHANGHAIProduct Origin :

CHINABEARING STEEL

Features

Strength in every alloy

Bearing steel is a high-strength alloy with high wear resistance, high toughness, high dimensional stability, easy processing and environmental protection.

High Hardness:Molds endure significant pressure and friction during operation. High hardness effectively resists plastic deformation and extends mold life.

Excellent Wear Resistance: Intense friction occurs between the mold and the blank. High wear resistance reduces wear, maintains mold precision, and improves product surface quality.

High Strength: Molds must withstand substantial impact loads and alternating stresses. High strength prevents mold cracking and deformation.

Good Toughness:Molds are prone to brittle fracture under impact loads. Good toughness enhances the mold's impact resistance.

Excellent Dimensional Stability: Molds must maintain stable dimensions under varying temperature conditions to ensure product precision.

Good Machinability:Molds undergo complex machining processes. Good machinability improves production efficiency and product quality.

Choose us for an efficient, durable, and worry-free cutting experience!

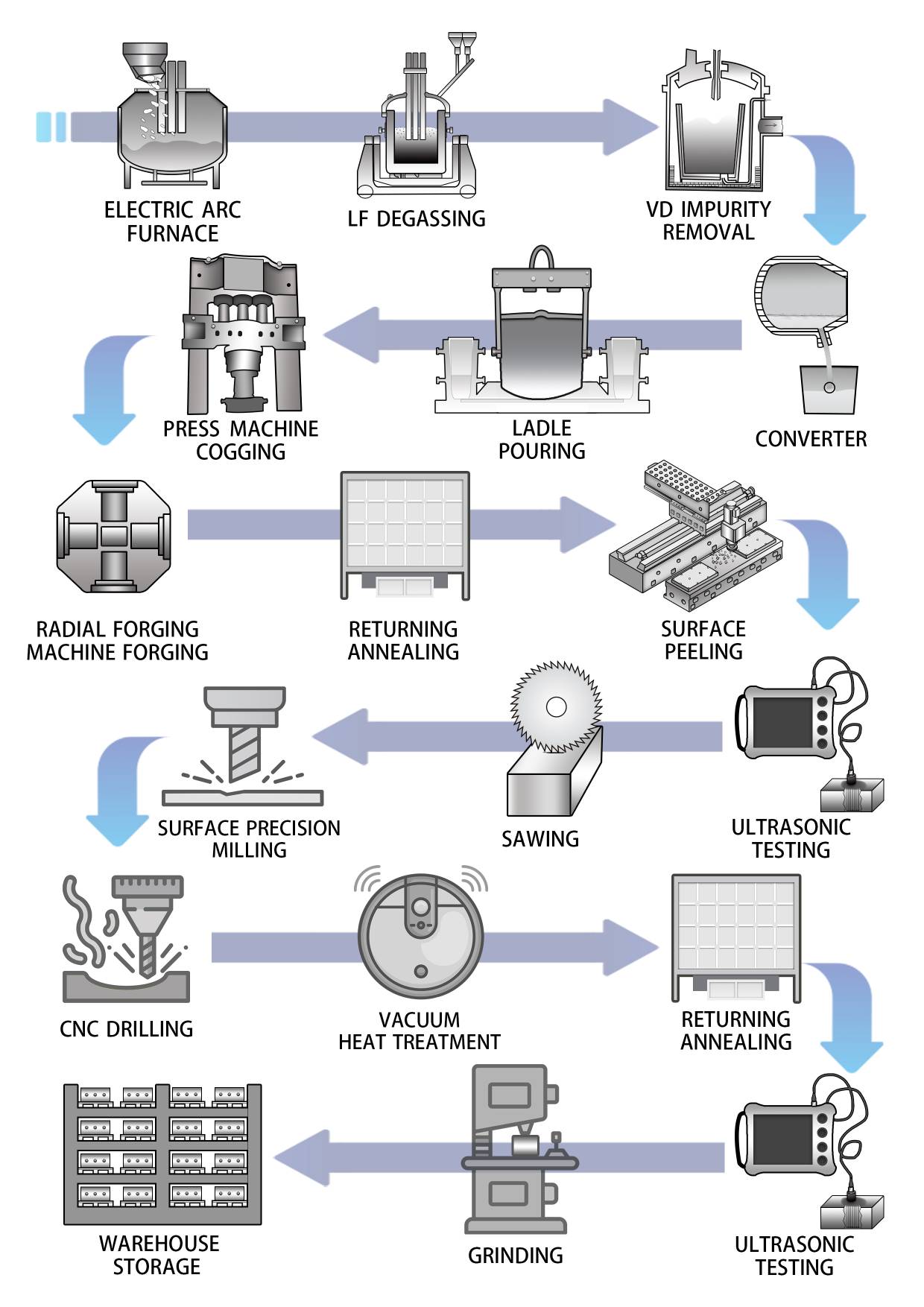

Working process

Parameter

| Grade | C | Si | Mn | P | S | Cr | Ni | Cu | V |

| G55SiMoV | 0.20 | 0.99 | 0.41 | 0.011 | 0.004 | 0.07 | 0.01 | 0.01 | 0.2 |

The data in the chart are measured values and may have fluctuating differences.

Details

Technology

1. What is mold steel?

Mold steel is a specialized type of steel used for manufacturing molds (such as stamping, forging, and die-casting molds). It possesses high hardness, strength, wear resistance, toughness, and dimensional stability.

2. What are the main types of mold steel?

Cold work mold steel:Used for room-temperature molds, such as stamping molds (common grades: Cr12, Cr12MoV).

Hot work mold steel:Used for high-temperature molds, such as die-casting molds (common grades: H13, 5CrNiMo).

3. How to choose the right mold steel?

Selection should consider factors such as mold type, working conditions (temperature, stress, wear), processing techniques, and cost.

4. How to extend the service life of mold steel?

Choose the right material and optimize design.

Follow standardized processing and ensure proper usage, avoiding overloading and performing regular maintenance.

5. What are the development trends in mold steel?

High performance:Improve hardness, strength, wear resistance, and fatigue resistance.

High precision: Enhance dimensional accuracy and surface quality.

Green and environmentally friendly: Develop low-alloy, pollution-free mold steel.