Cr12MoV steel has become the mainstream choice for precision cold working molds due to its high wear resistance, moderate toughness and excellent dimensional stability. It is especially suitable for scenarios with strict requirements on edge retention and mold life.

Made of high-quality alloy tool steel or high-speed steel, it has undergone special heat treatment process and has extremely high hardness and wear resistance. Mainly used for straight-line cutting of scrap steel

Customized :

YESApplication :

SCRAP RECYCLINGOrder(MOQ) :

1 pieceLead Time :

30 DAYSShipping Port :

SHANGHAIProduct Origin :

CHINASCRAP METAL SHEAR BLADE

Features

precision in every cut

Guillotine Gantry Shear Blade Mainly used for straight-line shearing of metal sheets:

High strength and high wear resistance: Made of high-quality alloy tool steel or high-speed steel, and after special heat treatment process, the blade has extremely high hardness and wear resistance, and the service life is extended.

High precision: Precision grinding ensures the dimensional accuracy and shape and position tolerance of the blade, ensuring the straightness and cutting quality of the sheared plate.

Multiple specifications available: Blades of different lengths, thicknesses, and cutting edge angles can be customized according to customer needs to meet the shearing needs of plates of different thicknesses and materials.

Easy installation: Reasonable design, easy and quick installation, easy for users to replace and maintain

Choose the Demolition Shear Blade to experience efficient and precise cutting performance!

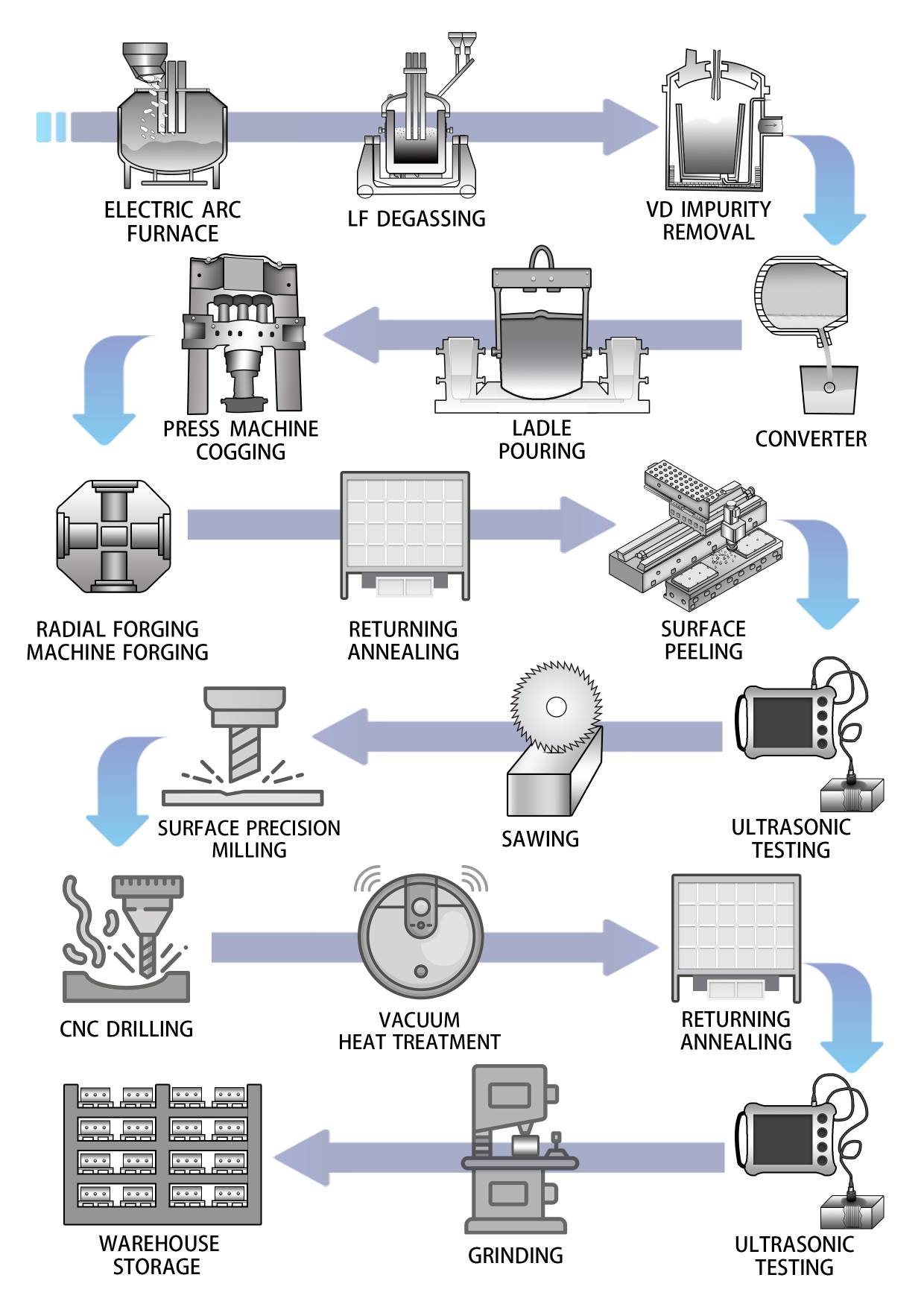

Working process

Parameter

Cr12MoV steel, renowned for its exceptional performance and wide-ranging applications, has become an indispensable material in moder industry,With continuous technological advancements, it is bound to play an even greater role, contributing to industrial progress, Standing out in numerous application scenarios.it has become synonymous with reliability and efficiency.

Application

>Mold Manufacturing: Used for manufacturing hot work molds, cold work molds, and plastic molds, meeting the requirements of high strength, high wear resistance, and heat resistance.

>Cutting Tools: Used for manufacturing key components such as gears, shafts, and connecting rods, which endure high loads and complex stresses.

>Wear-Resistant Parts: Used for manufacturing cutting tools such as turning tools, milling cutters, and drill bits to improve processing efficiency and tool lifespan.

Chemical Composition

| Grade | C | Si | Mn | P | S | Cr | Ni | Cu | V |

| Cr12MoV | 1.58 | 0.36 | 0.27 | 0.025 | 0.009 | 11.28 | 0.21 | 0.11 | 0.21 |

Macroscopic inspection

>Low Magnification

| Center Porosity (Grade) | Chain Segregation (Grade) |

| 2.0 | 1.0 |

Mechanical Propertiesa

>Quenching Hardness

| Quenching Hardness HRC |

| 61.5 | 60.0 |

The data in the chart are measured values and may have fluctuating differences.

Details

Technology

1.Where is this blade commonly used?

It is widely used in metal recycling plants, scrap yards, demolition sites, and steel processing factories.

2.Can it cut stainless steel and hardened steel?

Yes, but for high-hardness materials, a specialized high-strength blade is recommended.

3.How does a Crocodile Shear Blade compare to a Guillotine Shear Blade?

Crocodile Shear Blades are designed for heavy-duty scrap cutting, while Guillotine Shear Blades are used for precise sheet metal cutting.